Cycling thermoelectric modules (TM)

At present thermoelectric modules find increasingly wider use in what is known as cycling conditions. They are characterized by high heating/cooling rates of 5 to 20 degree/sec; besides, Peltier modules are to ensure stable work in reversal polarity of supply voltage conditions during hundreds of thousands of cycles.

Such applications of thermoelectric modules may be:

- medical equipment for PCR used for DNA analysis

- testing equipment for temperature tests of electronic devices

- analytical equipment

Launch of ТМ series of cycling thermoelectric modules was largely due to the development and application of the following design and technological innovations:

- advanced polycrystalline thermoelectric materials with high mechanical strength, obtained using the powder metallurgical technique

- patented technology for the manufacture of glued Peltier modules for relieving mechanical stresses taking place on operating module

- designed and implemented technology of multilayer antidiffusion barriers resistant to thermal stresses

- gold-plated semiconductor thermoelectric dices to avoid thermoelectric module soldering defects

- thermoelectric modules soldered using low active rosin fluxes with minimum ion component concentrations for enhanced corrosion resistance of modules

- precise finish high quality lapping to ensure thickness, parallelism and flatness of Peltier module working surfaces to enable a good thermal contact with the cooled object and the heat sink

- 6-stage washing with a variety of solvents to remove residual flux and ensure corrosion resistance of modules;

- module quality control at all production operations, regulated by the Quality Assurance for thermoelectric modules (basic level)

- application of only those components that have been approved for use by the EU RoHS Directive

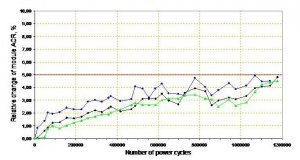

Due to the above innovations, ТМ series thermoelectric modules are highly reliable when used in cyclic temperature change conditions. Provided below as an example are the results of reliability tests of ТМ-127-1.4-6.0 М modules.

The capabilities of TM-series thermoelectric modules to withstand high cycling are shown for module

TM-127-1.4-6.0 M ( I=0.8Imax, T heat sink =40+5oC, Tcold=20/100oC, cycle time = 60sec)

Reliable operation of Peltier modules in temperature cycling conditions depends on the operating conditions, cycle temperature and time parameters, thermoelectric module dimensions and component parts.

The required thermoelectric module types are selected from the Table given below, based on the marking ТМ-ААА-ВВ-СС М, where:

- TMС — cyclic thermoelectric module

- AAA — number of thermocouples

- BB — dice cross section, mm

- CC — current at maximum temperature differential ΔT, А

- М — modules manufactured using the patented glue technology